It’s safe to say that one of the number one rules in the realm of Health and Safety is incident prevention. If not made aware of them, chemical hazards can present a detrimental threat to life and impede on safety at the workplace. Occupational Safety Health Administration (OSHA) has made it a requirement under their Hazard Communication Standard (HCS) that any and all chemicals being produced or imported must be classified. Further, all employers must take the responsibility to engage their employees in chemical hazard safety by means of educating them on effective chemical labeling , safety data sheets , and thorough health and safety employee training as explained in section 1910.1200 of the Occupation Safety Health Administration Hazard Communication Standard. When your team is preparing their Job Safety Analysis or Job Hazard Analysis it maybe appropriate to review and confirm that your Written Hazard Communication Program is current and up to date.

Written Hazard Communication Program 1910.1200(e)

These hazard communication programs are required to be available, upon request, to all employees, their designated representatives, the Assistant Secretary and the Director. If the employee is traveling off site for a task, then the hazard communication program can remain at the primary work location. This document must include the following:

- Completed Safety Data Sheet with A list of the hazardous chemicals known to be present

- Employer methods for communicating the hazards of non-routine tasks to employees

- The methods the employer will use to provide the other employer(s) on-site access to safety data sheets for each hazardous chemical that employees can be exposed to within a multi-employer workspace

- Precautionary measures that need to be taken to protect employees during the workplace's normal operating conditions and in foreseeable emergencies

Labels and Other Forms of Warning 1910.1200(f)

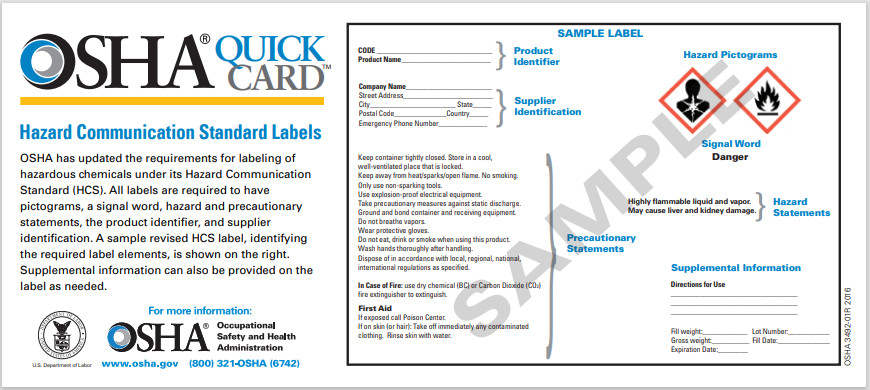

The Occupational Safety Health Administration revamped their Hazard Communication Standard as of June 1 st 2015 which works in unison with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). All chemical manufacturers and importers are required to evaluate and classify all chemicals being handled to further promote hazard safety. Labels on shipped containers must include the following:

Product Identifier

The product identifier is represented by either the chemical, common, or trade name. It’s also common to see the identifier include the code number and/or batch number

Signal Word

A signal word is used to indicate the level of severity of the specific hazard and currently there are only two words authorized for this use which are “Danger” and “Warning”. Danger is used for a more severe hazard while warning indicates a less sever hazard and only one signal word will be used for each hazard.

Hazard Statement(s)

This statement is intended to describe the nature of the hazard(s) of the chemical that is present and explain the degree of the hazard. One simple example of this statement would be “toxic if ingested”.

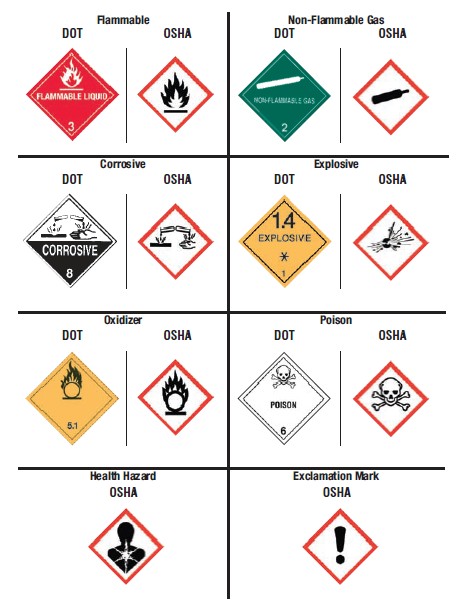

Pictogram(s)

This is simply an image used to grab the viewers' attention. The GHS acknowledges 9 different images while the Occupational Safety Health Administration only utilizes 8 of these images (all below, except for “Environment”). Each pictogram also has a corresponding description to further inform the viewer what danger(s) is associated with the chemical.

The DOT uses pictograms as well on the shipping containers used to transport hazardous products. They are not the same images as used by GHS or OSHA, but have been made to be very similar. These DOT pictograms may be seen either in addition to or instead of the OSHA/HCS pictograms.

Precautionary Statement(s)

Used to describe the recommended steps that should be taken to reduce and/or prevent the potential adverse effects resulting from contact with the hazardous chemicals or in the event of the chemical not being stored or handled properly.

Four types of precautionary statements:

- Prevention

- Response

- Storage

- Disposal

Precautionary statements are traditionally made to be independent, but the Occupational Safety Health Administration allows the combining of them, using a specific order of precedence, or excluding certain statements all together if need not apply.

Contact Information

OSHA requires that the name, address, and telephone number of the chemical manufacturer, importer, or other responsible party be provided.

Linked below is for quick access to a sample label for hazardous chemicals and can be kept on file as a reminder to include all necessary elements to be compliant. OSHA Quick Card:

OSHA Quick Card (PDF Download)

Chemicals Exempt from the HCS 1910.1200(b)(5) / 1910.1200(b)(6)

Not all chemicals are created equal, and some do not need to be held to these OSHA standards. Below is a list of chemicals that are exempt from the Hazardous Communication Standard.

- Any pesticide subject to labeling requirements determined by the Environmental Protection Agency (EPA)

- Any chemical substance or mixture subject to labeling requirements determined by the EPA

- Any food, food additive, color additive, drug, cosmetic, or medical or veterinary device or product subject to labeling requirements determined by the Food and Drug Administration or the Department of Agriculture

- Any distilled spirits, wine, or malt beverage intended for nonindustrial use subject to labeling requirements determined by the Bureau of Alcohol, Tobacco, Firearms and Explosives

- Any consumer product or hazardous substance subject to labeling requirements determined by the Consumer Product Safety Commission

- Agricultural or vegetable seed treated with pesticides subject to labeling requirements determined by the Department of Agriculture

- Any hazardous waste as such term is defined by the Solid Waste Disposal Act as per the Environmental Protection Agency

- Any hazardous substance as such term is defined by the Comprehensive Environmental Response, Compensation and Liability Act (CERCLA)

- Tobacco or tobacco products

- Wood or wood products

- Ionizing and nonionizing radiation

- Biological hazards

Safety Data Sheets 1910.1200(g)

Developed by the manufacturer and importers of these hazardous chemicals, safety data sheets are created for each chemical and consists of 16 separate sections of information:

Section 1: Identification

Section 2: Hazard(s) Identification

Section 3: Composition/information on ingredients

Section 4: First-aid measures

Section 5: Fire-fighting measures

Section 6: Accidental release measures

Section 7: Handling and storage

Section 8: Exposure controls/personal protection

Section 9: Physical and chemical properties

Section 10: Stability and reactivity

Section 11: Toxicological information

Section 12: Ecological information

Section 13: Disposal considerations

Section 14: Transport Information

Section 15: Regulatory information

Section 16: Other information, including date of preparation or last revision

Employers are required to have the safety data sheet for every hazardous chemical their employees will be in contact with, readily available within the workplace. This can be in the form of a printout or electronically. While this document is needed to be OSHA compliant, it also contributes to the promotion of safety at the workplace.

Employee Information and Training 1910.1200(h)

Employers have an obligation to their employees to provide them with effective and adequate health and safety training on the chemical hazards they may encounter and how to handle them appropriately to avoid any negative consequences. The better you train your worker on these potential hazards, they safer they will be which in turn will make the work completed efficiently. Generally speaking, training topics should include the Hazard Communication Standard, the Hazard Communication Program, operations at risk of contact with hazardous chemicals, and the locations where the worker can find the hazard evaluation procedures and applicable safety data sheets.

An easy and efficient way to keep employee’s safe is through Job Safety Analysis worksheets (JSA). No matter how big or small the operation is, Job Safety Analysis worksheets allow employers to put together straightforward outlines of potential chemical, physical, biological, and radiological hazards. Go to https://www.jsabuilder.com/ to start your free 30-day trial and test out building your own custom Job Safety Analysis worksheet today!

JSABuilder is a state-of-the-art online job safety analysis app to assist in preparing your Job Hazard Analysis (JHA), Job Safety Analysis (JSA) or Activity Hazard Analysis (AHA). Set up a free trial account today and follow us on Twitter @JSABuilder, where we Tweet about Health and Safety, provide Safety tips, and updates on current Health and Safety topics.

Images, links, brands discussed or displayed in this article are not endorsements or recommendations. They are for illustration of various products and types of products. JSABuilder does not recommend or express any opinion as to the applicability to any given use case or job hazards.