The OSHA Safe+Sound program was developed to promote proactive health and safety programs in the workplace to manage hazards with a goal of preventing injuries and illnesses. To manage hazards, it is necessary for managers and workers to have the ability to recognize potential hazards that they need to mitigate in an appropriate manner. When we think of “ hazard identification, ” often our context shifts towards “hazards” as indicated and defined by placards on delivery trucks we encounter constantly on roads, which apply to their cargos. These placards are important, but they refer to chemical hazards which workers need to be aware of and understand, but “hazards” as it applies to most workers is a much broader topic. Workers need to consider all physical hazards of which chemical hazards is just a subset. To keep our workers safe, we need to expand our conversations to inform and train workers on all types of physical hazards .

All hazards have one common attribute, they are agents, factors or circumstances that can harm workers. They are all triggered as a consequence of some form of energy. Therefore, if workers are aware of the different forms of energy, they can apply their understanding to identify and control potential hazards related to specific forms of energy. That will help to facilitate engineering mitigations to reduce or eliminate potential hazards . If workers are perceptive, vigilant, and observant they will probably do a great job preventing accidents and stay Safe+Sound!

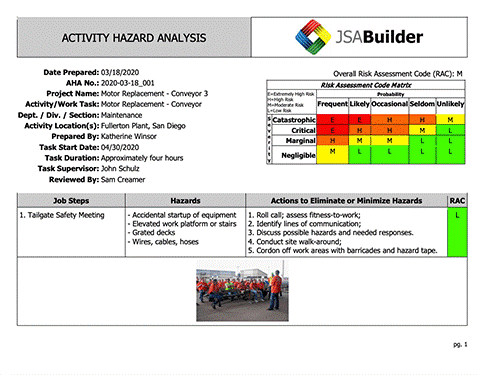

The best time to start identifying potential hazards is in the planning stages for tasks or projects prior to the start of work. To help identify hazards, it is very helpful to seek the assistance of a tool such as the Job Safety Analysis (JSA) to help efficiently complete the process in an organized fashion. The JSA, also known as a Job Hazard Analysis (JHA) or Activity Hazard Analysis (AHA) , is an essential tool for guiding and promoting safe behaviors in the workplace. JSAs are useful as a great tool to promote team conversations involving all competent and inexperienced workers to review potential task risks and develop the mitigating responses to eliminate or reduce those potential risks. These safety conversations also help reduce complacency by focusing the work team on the current conditions at task locations, which may be different than those perceived while organizing the project or task. The workers need to perform their work tasks using safety plans that are up to date and consistent with current conditions.

|

|

During every project planning process, all forms of energy should be considered to help identify and prevent potential hazards. A brief description of several forms of energy, which can potentially cause hazards for workers is presented below. This list of forms of energy can be very beneficial if workers are trained and made familiar with them prior to preparing for all proposed work tasks. The list of various forms of energy follows:

- Motion - is the instance of movement such as for example, movement of vehicles or equipment that then become a hazard if a worker were to step into the path of a moving vehicle.

- Gravity - is the natural attraction of objects to earth; a phenomenon which gives weight to physical objects. The weight of an object or worker at a height above the surrounding area or objects can result in potential fall hazards where a worker could possibly fall off a ladder or have an over-head object fall on them for example.

- Pressure - is the force applied perpendicular to the surface of an object such as a tank or pipe, which if penetrated by a rupture allowing the release of the contents, could potentially result in a hazard to anybody in close proximity to the rupture, for example.

- Heat and Cold - throughout the year, weather brings heat and cold waves that present hazards to workers where overexposure can be a risk, especially when they are unprepared.

- Noise- is a fairly common occupational hazard that often is or should be discussed since most work activities result in some level of noise that may require hearing protection.

- Electrical - electrical energy presents a danger to workers from potential electrocution, shock and burns and can be encountered almost anywhere, indoors or outdoors. The presence of an electrical hazard is not always obvious. Most electrical hazards are related to power systems at work sites, however, naturally occurring lightning can also present a hazard mainly at outdoor locations.

- Chemical - exposure to some chemicals can potentially cause acute and detrimental health effects that can be long-term in nature. The potential hazards are many, diverse, and specific to the work activity. Workers can be exposed to chemical reactions resulting from combining compounds, or by exposure to compounds that themselves can potentially act as some type of toxin or hazard. Careful thought needs to be invested into potential chemical hazards since some types of chemicals are present on most worksites.

- Ergonomic - these hazards are those that can potentially pose a risk of injury to the musculoskeletal system. This is often a consequence of repetitive motions by workers.

- Radiation - the most common type of radiation is solar radiation, which is a source of ultraviolet rays that with prolonged exposure can cause damage to worker’s eyes and skin most commonly. Ionized radiation is another less common potential hazard that results from subatomic particles or electromagnetic waves that have sufficient energy to ionize atoms or molecules.

- Biological- the most common biohazards workers encounter are insects or snakes, which are often present on many worksites. Biohazards may also consist of toxins or microorganisms that can adversely affect worker health as well.

- Vibration - continuous exposure to high levels of vibration from operation of tools and equipment can, for example, cause direct injury to workers’ fingers and hands resulting in loss of dexterity and feeling.

When considering and reviewing potential hazards resulting from different types of energy, authoritative sources of information should be utilized. The relevant information when used with a Job Safety Analysis provides an essential tool for systematically identifying site risks then guiding and promoting safe behaviors in the workplace. A quick and inexpensive way to access a simple internet-based tool to help create your own JSAs, is to test a time-proven tool available at JSABuilder.com , a great resource all employers should utilize. This tool is an easy-to-use database-driven customizable template, where the user can create custom Job Safety Analyses that are then available to be accessed by their distributed workforce. Once a JSA, is created, it resides in a secure library of JSAs where it and others created by the user are available for update modifications, or later for future modification and possible use for new or different jobs. It’s worthwhile for employers to invest the time and thought to create or modify JSAs in JSABuilder’s simple and efficient process.

JSAs, are a useful tool that can aid the identification of changed conditions, which can help a work team to develop and agree on revised mitigations at their worksite. Those mitigation revisions can then be immediately documented with a management of change (MOC) annotation right on the JSA. That facilitates helping everybody to complete their tasks safely, in an efficient manner. Performing these MOC steps during reviews help to keep all team members engaged in thinking about their current work tasks and help eliminate potential hazards. A JSA worksheet provides employers so much value so inexpensively, it’s difficult to understand why anyone would not use a Job Safety Analysis for every project task.

Go to jsabuilder.com and test the referenced JSA software for free , and help your team work safely and go home at the end of each work day without harm . Follow us on LinkedIn and Twitter @JSABuilder, where we tweet about Health and Safety, post Safety tips, and provide updates on current Health and Safety topics. We also highly recommend that you try one of our other top safety tools at www.LOTOBuilder.com today, where our database-driven Lockout Tagout tool is currently available for a FREE 30-day trial, which will allow you to manage your lock out tag out program from start to finish. Easily enter your workers, equipment and procedures to build an entire LOTO program . Save time and money using LOTOBuilder and help your workers to work safe.

Note: images, links, brands discussed or displayed in this article are not endorsements or recommendations. They are for illustration of various products and types of products. JSABuilder does not recommend products, does not endorse, or express any opinion as to the applicability to any given use case or job hazard. Again, consult your safety professional to obtain authoritative opinions on applicability, selection and fitting of all the various types of PPE, then work smart and safe.